Having trouble with your DTF transfers not sticking, smudging, or cracking? You’re not alone. In this blog, we’re breaking down the top 3 DTF printing mistakes we see most often, and exactly how to fix them.

Getting Started with DTF Printing

There’s no denying it. DTF printing has taken custom apparel to the next level. The colors pop, the versatility is unbeatable, and the creative possibilities feel endless. But let’s be real, it’s not without a few challenges along the way.

At IT Supplies, we talk to people every day who are either getting started with DTF or troubleshooting transfers that just won’t come out right. The good news? Most problems can be traced back to a few common mistakes.

In this blog, we’re going to share the top three DTF printing problems we see most often, explain why they happen, and walk you through simple, reliable fixes. If you can avoid these three pitfalls, your transfers will look sharper, last longer, and perform better on every press.

Mistake #1: Poor Adhesion

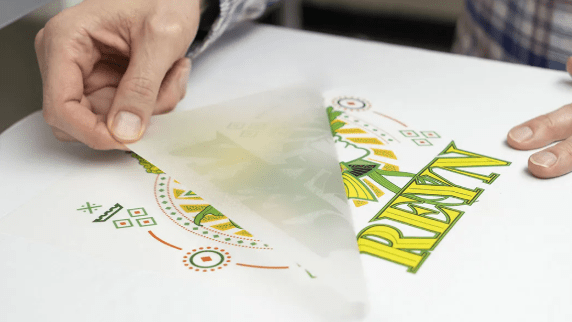

Let’s start with the biggest one. If you’ve ever finished a transfer and peeled your film only to find that the design isn’t sticking to the shirt, you’re not alone. Poor adhesion is by far the number one DTF printing complaint we hear from customers.

So, what causes it? The most common culprits are incorrect heat or pressure settings.

DTF transfers need consistent heat in the range of 280 to 320°F and a medium-to-firm pressure, around 30 to 50 PSI. If your heat press isn’t hot enough, or if your pressure is too light, your adhesive powder won’t properly bond to the fabric. You’ll end up with a transfer that looks good at first but starts to peel or lift after a few washes.

Another sneaky cause is old or uneven powder. Adhesive powder absorbs moisture from the air over time, and once it gets clumpy, it won’t melt evenly. The result is patchy adhesion that leaves parts of your design barely attached to the garment.

How to Fix Poor Adhesion

- Check your powder: Always use fresh adhesive powder and make sure it’s stored in a dry, sealed container.

- Apply powder evenly: Uneven coverage means uneven bonding. A quick shake test before curing helps ensure full, even coverage.

- Dial in your press settings: Test your heat press with a temperature gun to confirm accuracy. Adjust your pressure to medium-firm.

- Run test prints: Each press behaves slightly differently, so run a few tests before starting production.

When you get it right, your transfer should feel like part of the fabric rather than sitting on top of it. That’s your sign of perfect adhesion.

Mistake #2: Ink Bleeding or Smudging

Next up is a frustrating one that can ruin an otherwise great print: ink bleeding or smudging.

You might notice colors that feather out, edges that aren’t crisp, or a smeary look to your design. This typically happens when you’re laying down too much ink or when the film isn’t dried properly before applying the adhesive powder.

When ink stays too wet, the powder sticks unevenly and creates a blotchy mess. The result? A print that never cures correctly and loses vibrancy fast.

How to Prevent Ink Bleeding

- Check your print settings: Make sure your ink limits are dialed in correctly for your specific printer model and film. Too much ink saturation can quickly overwhelm your film.

- Allow for proper drying: Don’t rush the drying stage. After printing and applying your powder, your transfer should have a matte, orange-peel texture before you press it. If it still looks glossy or feels tacky, it needs more curing time.

- Control your environment: Humidity can play a big role. Too much moisture in your workspace can slow down drying times and affect ink behavior.

A great tip we share with customers is to use a consistent curing setup. If you’re still manually applying powder and baking films one by one, consider automating your process.

Mistake #3: Cracking or Lifting

Few things are more disappointing than washing a shirt for the first time and seeing your design start to crack or peel. This is what we call cracking or lifting, and it’s one of the top complaints among new DTF users.

The root cause can usually be traced back to one of three issues:

- Improper curing

- Incompatible fabrics

- Uneven powder coverage

If your transfer hasn’t been cured long enough, or if the curing temperature is inconsistent, your ink and adhesive won’t properly set. That weak bond leads to cracking during washing or stretching.

Using incompatible fabrics can also be a problem. Not every fabric responds the same way to high heat. If the garment can’t handle the required temperature range, it may cause the transfer to warp or lift.

Finally, uneven powder coverage is a silent culprit. Areas with little to no adhesive simply won’t bond to the fabric, causing those annoying edges to peel up.

How to Fix Cracking and Lifting

Use DTF-friendly fabrics: Stick with polyester, cotton, or blends that can handle 300°F or higher.

Double-check curing settings: Always cure your prints according to the manufacturer’s recommendations. Consistency is key.

Ensure full powder coverage: Take time to shake or spread your powder evenly before curing.

When in doubt, do a wash test before full production. A properly cured and bonded transfer should survive multiple washes without losing color or flexibility.

Pro Tip: Automate for Consistency

A lot of these mistakes come down to inconsistency in temperature, powder application, and curing. The easiest way to eliminate these variables is through automation.

Automated shaker and curing units ensure that every transfer gets the same powder coverage and curing time. They also help maintain a cleaner workspace and save time on repetitive steps.

At IT Supplies, we offer automated shaker and curing systems that pair perfectly with the top DTF printers. Whether you’re running an Epson SureColor F2270, G6070, or Roland’s BY-20 and TY-300, there are bundle options designed to streamline your process and improve results.

If you’re serious about DTF printing, an automated setup is one of the best investments you can make for consistent, professional-quality transfers.

Why Work with IT Supplies?

Here’s something we really want our customers to know: when you buy from IT Supplies, you’re not just getting a printer. You’re getting a team.

Our technicians and textile sales reps are some of the most knowledgeable in the business. We’re here to help you every step of the way, whether you’re setting up your first printer, dialing in your heat press settings, or troubleshooting a tricky transfer.

We take calls every day from DTF users who just need a little guidance, and we’re always happy to help. That’s what sets IT Supplies apart.

If you’re near Rolling Meadows, Illinois, you can stop by our showroom to see printers in action and test out equipment. If you’re not local, we’re still just a phone call or email away.

Shop DTF Printers at IT Supplies

Ready to take your DTF setup to the next level?

You can browse our full lineup of DTF printers, powders, films, and curing equipment right here.

DTF printing is an incredible technology that’s changing the game for garment decorators, but like any process, it has its challenges. The key is understanding where things go wrong and knowing how to fix them before they impact your results.

By mastering your heat, pressure, powder coverage, and curing, you can prevent most of the common DTF problems we see every day. And when you do run into a snag, just remember that our IT Supplies team is here to help you troubleshoot and get back to printing!

IT Supplies is your one-stop shop for everything you need to achieve the perfect print. We partner with top manufacturers to bring you the best in printing technology, including Eco-Solvent, Latex, UV, and Aqueous printers from EPSON, HP, and Canon. Our lineup also features a wide selection of Dye-Sublimation, DTF, and DTG printers from EPSON and HP. Explore our full range at www.itsupplies.com or by giving us a call at 1-800-771-9665!