Direct-to-Film (DTF) printing is revolutionizing fabric printing with vibrant and detailed images. However, the challenge of achieving a soft, flexible feel remains. Learn how to tackle this issue using Digital Factory’s ‘knock-out’ feature and the right TPU powder for stunning, breathable prints.

What is DTF Printing?

DTF (Direct-to-Film) printing is a cutting-edge technique for transferring detailed designs onto various fabrics, including cotton, polyester, and blends. It uses water-based pigment inks to print onto PET film, which is coated with hot-melt adhesive powder, melted, and cured. This method produces vibrant, durable prints, making it a versatile choice for the garment industry.

Understanding the Problem: Heavy, Stiff Hand Feel

A common challenge with DTF printing is the heavy, stiff texture caused by solid layers of ink. Without negative space, the print can feel plasticky and inflexible, detracting from the garment’s comfort and wearability. Addressing this issue is key to creating high-quality prints that look and feel great.

The Knock-Out Feature in Digital Factory Software

Digital Factory software includes a powerful ‘knock-out’ feature designed to alleviate the stiffness in DTF prints. This tool removes black portions from a design, introducing negative space and reducing the ink density. The result is a breathable, flexible print that enhances the garment’s overall feel.

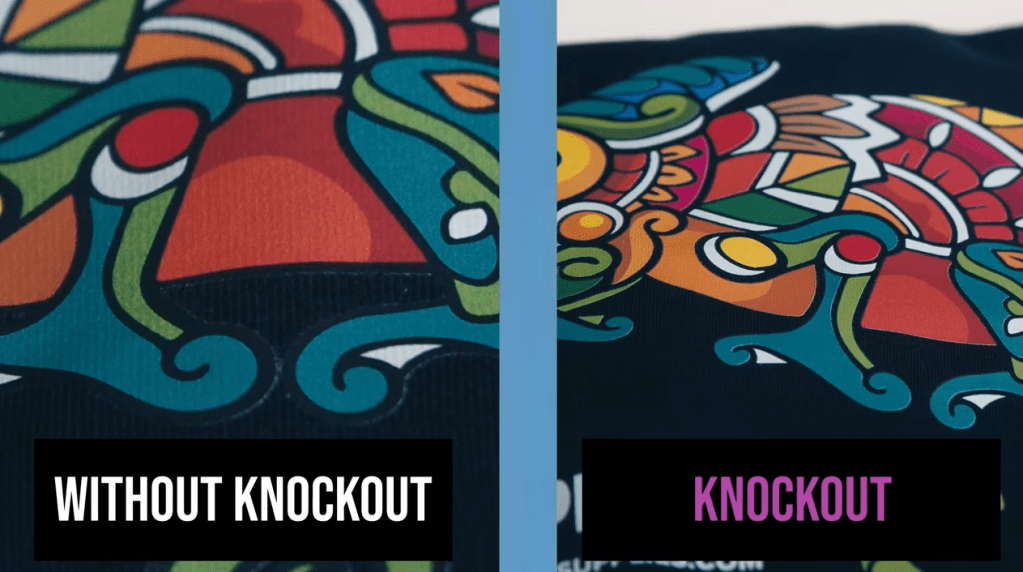

Here’s a comparison:

- Without Knock-Out: The design appears as a solid mass of ink, leading to a heavy and stiff print.

- With Knock-Out: The design includes intentional gaps, creating a soft and balanced feel.

This simple adjustment can significantly improve the print’s hand feel, making it more comfortable for everyday wear.

Enhancing Prints with the Right TPU Powder

Choosing the right TPU powder is essential for achieving the perfect balance of softness, flexibility, and durability in your DTF prints. TPU powders act as a bonding agent, ensuring the ink adheres well to the fabric while maintaining a comfortable hand feel.

STS #5 Polyurethane Powder

This powder features extra-fine particles, allowing for a soft, smooth print that feels natural on the fabric. It’s an excellent choice for applications where comfort is a priority, such as t-shirts and other wearable garments.

STS #6 Polyurethane Powder

With slightly larger grains, this powder creates a thicker layer, ideal for blocking dye migration on dark or vibrant fabrics. It ensures your designs remain crisp and vivid without color bleeding, making it perfect for challenging substrates.

Both powders offer exceptional wash durability, keeping prints intact and vibrant even after 50 washes or more.

Spotlight on the STS XPD-924D Printer

The STS XPD-924D Printer is a game-changer in the DTF printing industry. Its state-of-the-art technology delivers stunning print quality at a production speed of 182 square feet per hour, making it an excellent choice for high-volume printing.

This printer ensures consistency and precision, which is crucial when combining techniques like the knock-out feature and high-performance TPU powders. With the XPD-924D, you can achieve professional-grade results efficiently and reliably.

Combining Techniques for the Best Results

Achieving ultra-soft DTF prints requires a thoughtful combination of tools and techniques. By using the knock-out feature to introduce negative space and selecting the appropriate TPU powder for your needs, you can create prints that not only look stunning but also feel comfortable to wear.

For example:

- Use #5 Polyurethane Powder for soft, breathable prints on light-colored fabrics.

- Opt for #6 Polyurethane Powder to prevent dye migration on dark, vivid fabrics.

Pair these methods with the STS XPD-924D Printer for unparalleled efficiency and quality. Together, these tools empower you to produce superior prints that meet the highest standards of comfort and durability.

Conclusion

Creating ultra-soft DTF prints is a combination of art and science. By leveraging the knock-out feature in Digital Factory software, selecting the appropriate TPU powder, and utilizing the cutting-edge STS XPD-924D Printer, you can achieve professional-quality results that feel as good as they look.

Attention to these details will help elevate your prints, ensuring they are vibrant, durable, and comfortable. With these tips, you can tackle the challenges of DTF printing and produce garments that stand out for all the right reasons.

FAQs

1. How does the knock-out feature improve the print’s hand feel?

The knock-out feature introduces negative space into the design, reducing ink density and creating a softer, more flexible print.

2. What fabrics work best with DTF printing?

DTF printing works on a wide variety of fabrics, including cotton, polyester, and blends. It’s versatile and suitable for most textiles.

3. Can I achieve similar results without using Digital Factory software?

While other software might offer similar tools, Digital Factory’s knock-out feature is specifically optimized for DTF printing, making it a preferred choice for achieving soft prints.

4. How do I prevent color migration in dark fabrics?

Using STS #6 Polyurethane Powder helps block dye migration, keeping designs crisp and vivid on dark or vibrant fabrics.

5. What is the shelf life of TPU powders?

TPU powders typically have a long shelf life when stored in a cool, dry place, but it’s best to check the manufacturer’s recommendations for optimal use.

Ready to enhance your DTF printing game? Shop for the tools mentioned in this article to get started:

Don’t forget to watch our video for a visual guide to these techniques: Top Tips for Achieving Ultra-Soft DTF Prints.

IT Supplies is your single source solution for everything relating to the perfect print. We represent some of the top manufacturers in the industry. Our full lineup includes Eco Solvent, Latex, Flat Bed, and Aqueous printers by EPSON, HP, and Canon. We also carry a large selection of Dye-Sublimation and DTG Printers by both EPSON and HP. Visit us at www.itsupplies.com